Stone Lapping Unit for Ball Grooves of Hub Unit Ball Bearings

for outer ring grooves of double row angular contact ball bearings (continuous and simultaneou machining of double ball grooves by variable oscillation aixs)Standard Machining range :

Min. groove dia. 66 x Min. ID 58 x Breadth 20 - 60 mm,

Groove R 4 - 10 mm, Contact Angle 0 - 40°

BSFJ-07 PATENTED

Application

1) Double-row angular ball bearing hub unit

Main Features

- Can be easily installed either horizontally or vertically on general-purpose machines such as like NC lathes, allowing for greater freedom of use

- Adoption of parallel linkage creates an oscillation center at a remote point, realizing circular oscillation by using that point as the oscillating center of the workpiece. This eliminates the need for a mechanical axis center the workpiece oscillation center, and arms with large inertia are also not necessary.

- A rigid parallel linkage mechanism is used, and accuracy and efficiency are further improved by combining arc movement with 800 FPM oscillation. Oscillation angle, oscillation angle center conversion angle, and oscillation frequency can be easily set using the touch screen. Grindstone pressurization is controlled by an electropneumatic regulator, which also allows the conditions for multi-step rough and finish machining to be set, further improving accuracy and efficiency.

- Equipped with special bearings to extend the life of the unit, with special rubber seals to prevent coolant from infiltrating into bearings at joint sections due to falling abrasive grains

- Continuous, simultaneous machining of double-ball grooves has achieved a drastic reduction in machining time

- Use of CBN SH grindstones (produced by Mizuho), with durability approx. 20 times longer than conventional stones, for reduction in falling abrasive grains. An auto-slide stone head with a 17mm grindstone pressure stroke applied in combination with these grindstones makes continuous operation for long hours feasible.

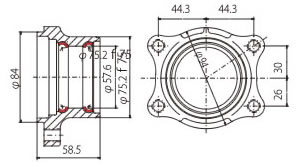

Work piece: Double-row angular ball bearing hub unit

Machine Specifications

| 1) Work piece | |

|---|---|

|

Double row angular contact ball bearing, Hub Unit O.D. (Continuous simultaneous machining of double ball grooves by variable oscillation axis) |

|

| 2) Machining range | |

| Minimum groove diameter | 66 mm |

| Minimum I.D. | 58 mm |

| Groove R | 4 - 10 mm |

| Width | 20 - 60 mm |

| Contact angle | 0° - 40° |

| 3) Oscillation unit | |

| Oscillation frequency |

Max. 800 fpm Automatic multi-step change-over |

| Oscillation angle | ±10°(±15°, ±20°Optional setting available) |

| Changeable angle of oscillation center | +45° - -45° |

| Oscillation drive motor | AC servomotor |

| 4) Stone head unit | |

| Automatic slide stone head, Pneumatic drive | |

| Stone pressurization |

Electropneumatic regulator control, Automatic multi-step change-over |

| Stone pressure stroke | 17 mm |

| Stone size | |

| Width | 5 - 10.5 mm |

| Crossover | 3 - 6 mm |

| 5) Machine size | |

| (W)440×(D)180×(H)240 mm | |

| 6) Unit weight | |

| 18 Kg | |

Note : Specifications are subject to change without notice.