Fully Automatic I.D. Centerless Stone Lapping Machine

for outer ring raceway of four-point contact (gothic arc groove), single-row deep groove and angular contact ball bearings, and doubel-row angular ball bearingsStandard application range :

(Full automatic)

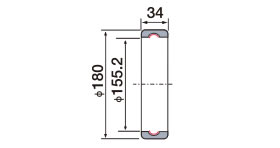

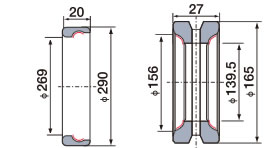

- Outer ring : OD 200 - 320 mm x Breadth 22 - 70 mm, Raceway curvature R 5 - 25 mm

(One cycle automatic)

- Outer ring : OD 200 - 400 mm x Breadth 22 - 70 mm, Raceway curvature R 5 - 25 mm

STK-400WT-A

Application

1) Deep Groove Ball Bearing

2) Angular ball bearing

Main Features

- Centerless stone lapping machine for outer ring raceways of ball bearings

- Infeed machining with plunge grinding. Inner diameter shoe, roller centerless support system.

- Equipped with direct-drive system in which oscillation arm is directly driven by AC servomotor

- The servomotor is driven with the latest control program, and oscillating stone head oscillates moves in smooth, sine-like curves. Backlash caused by conventional cam-type machines has been eliminated, and vibration has been minimized even at the high-frequency oscillation, achieving high-precision stone lapping. Additionally, the direct-drive system allows for angle settings and oscillating axis center position adjustment at the time of changeover to be performed easily by entering the work dimensions from the touch screen.

- Indexing of precise oscillation angles allows machining of gothic arc grooves with high precision, something which has been difficult until now

- Fully automatic stone lapping machine with work carrier slide unit

Work piece: Ball bearing outer ring

Machine Specifications

| 1) Work piece | |

|---|---|

|

Outer ring of four-point contact (gothic arc groove), ball bearing, single-row deep groove ball bearing, single & double-row angular contact ball bearing, angular thrust ball bearing, |

|

| 2) Machining range | |

| O.D. |

200 - 320 mm (Fully automatic) 200 - 400 mm (One cycle automatic) |

| Width |

22 - 70 mm (Manual loading for below 22mm and over 70mm) |

| Curvature |

R 5 - R 25 mm (Work piece of O.D. below150mm and of width over 50mm cannot be machined) |

| 3) Work piece support system | |

| O.D. roller centerless support or O.D. shoe centerless support system | |

| 4) Machining method | |

| Infeed type, Plunge cut | |

| 5) Main spindle unit | |

| Revolution |

Max. 960 rpm Automatic multi-step change-over |

| Motor | Inverter control |

| 6) Stone oscillation part | |

| Oscillation unit | Setting of oscillating frequency, oscillating angle, oscillating angle center is to be conducted through touch panel. |

| Stone oscillating axis | Directly driven by AC servomotor |

| Oscillation frequency |

Max. 500 fpm (±20°) Automatic multi-step change-over |

| Drive Motor | AC servomotor |

| Tool in/out slide unit | Axial direction positioning device |

| Drive Motor | Servomotor |

| Approach slide unit | Radial direction positioning device |

| Drive Motor | Servomotor |

| 7) Work carrier slide unit | |

| Work carrier shift system | |

| Stroke | 500 mm Hydraulic drive |

| 8) Work pressure unit | |

| Hydraulic drive | |

| 9) Stone head | |

| Auto-slide system | |

| Stone pressurization |

Electropneumatic regulator control, Automatic multi-step change-over |

| 10) Delivery unit inside M/C system | |

| 11) Machine size | |

| (W)2,460×(D)1,380×(H)2,030 mm | |

| 12) Machine weight | |

| 4,000 Kg | |

Note : Specifications are subject to change without notice.